Metal Injection Molding (MIM) is a modern method to make small and precise metal parts. It uses metal powder and a binder to form detailed shapes. MIM is gaining attention in India because it combines high quality with affordability. Industries like automotive, healthcare, electronics, and aerospace rely on this process. This article explores why Metal Injection Molding India is a top choice for businesses worldwide.

Why Metal Injection Molding India Delivers Quality

- Precision in Every Part

MIM ensures that every part is made with exact measurements. This level of precision is essential for industries that need small and detailed components.

- Durable and Strong Materials

The process uses strong metals like stainless steel and titanium. These materials make the parts long-lasting and reliable for different applications.

- Smooth and Ready-to-Use Finishes

MIM parts have smooth surfaces right out of the mold. This reduces the need for extra finishing steps, saving both time and money.

- Consistent Results in Large Production

MIM guarantees that every part produced matches the original design. This consistency is key for industries that need large batches of identical parts.

How Metal Injection Molding India Offers Affordability

- Low Material Waste

MIM uses just the right amount of material for each part. This minimizes waste and helps reduce costs.

- Cost Efficiency for Mass Production

The more parts you produce using MIM, the cheaper each part becomes. This makes Metal Injection Molding India a cost-effective solution for large-scale manufacturing.

- Affordable Labor and Operations in India

India has a skilled workforce with lower operational costs compared to other countries. This makes MIM in India both high-quality and budget-friendly.

- Fast and Efficient Production

MIM machines work quickly to produce thousands of parts in a short time. This efficiency helps businesses meet their deadlines without overspending.

Industries Benefiting from Metal Injection Molding India

- Automotive Industry

MIM is widely used in the automotive sector. It helps create strong and precise parts like gears, fuel injectors, and engine components. The affordability of Metal Injection Molding India is ideal for mass-producing these parts.

- Electronics Industry

Electronics require small and intricate parts like connectors, casings, and switches. MIM delivers these components with high accuracy and at a lower cost.

- Healthcare Industry

The healthcare sector relies on MIM for surgical tools, implants, and dental devices. These products must be safe and precise, and Metal Injection Molding India meets these requirements at an affordable price.

- Aerospace Industry

Aerospace parts must be lightweight, strong, and exact. MIM is used to produce brackets, engine parts, and other components that meet these demands.

Why Metal Injection Molding India Stands Out

- Skilled Professionals

India has a skilled workforce trained in advanced MIM techniques. They ensure parts are produced with accuracy and attention to detail.

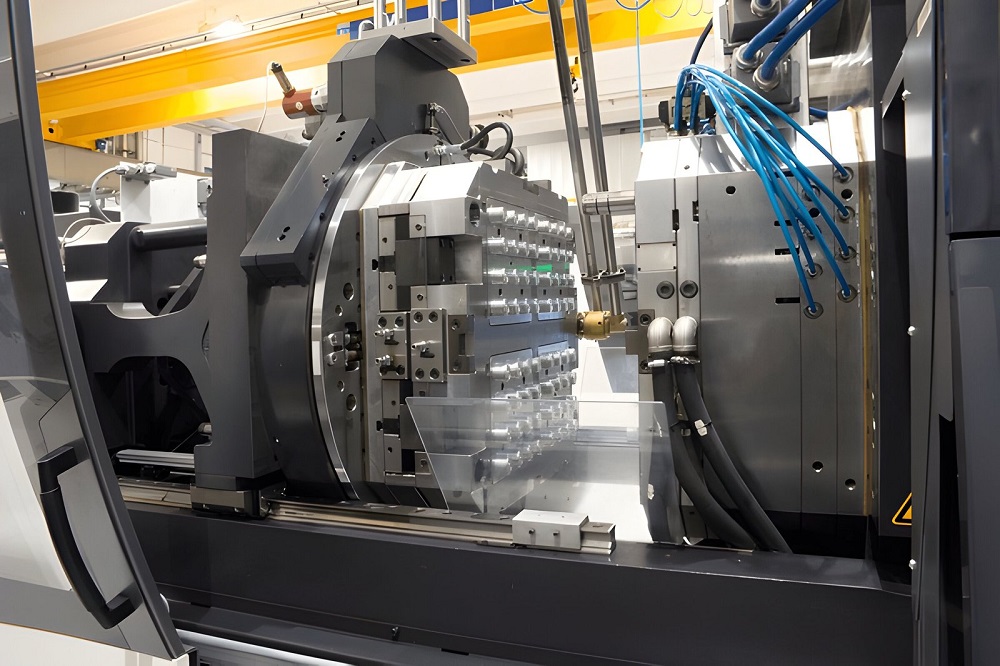

- Modern Technology

Indian manufacturers invest in state-of-the-art machines. These help produce high-quality parts quickly and efficiently.

- Low Production Costs

India combines affordable labor with efficient processes. This makes Metal Injection Molding India a preferred choice for global businesses.

- Sustainability

MIM in India uses eco-friendly practices like reducing waste and recycling materials. This supports sustainable manufacturing.

Advantages of Choosing Metal Injection Molding India

- High-Quality Products

The process ensures that every part is precise, durable, and meets international standards.

- Cost Savings

Businesses save money by reducing material waste and speeding up production. India’s competitive labor costs make MIM even more economical.

- Flexibility in Design

MIM supports creative and complex designs. Industries can create unique parts without increasing costs.

- Faster Delivery

The efficient process of Metal Injection Molding India allows companies to meet tight deadlines and deliver products on time.

Conclusion

Metal Injection Molding India is a game-changer for modern manufacturing. It combines precision, durability, and cost savings to meet the needs of industries like automotive, healthcare, electronics, and aerospace. With skilled workers, advanced technology, and low production costs, India is becoming a global leader in MIM. Metal Injection Molding India is the best choice for businesses looking for high-quality and affordable solutions.